Manufacturing & CPGDigital Engagement

Digital integration: The key to manufacturing M&A

To truly maximize deal value in manufacturing M&A, leaders must prioritize proactive digital infrastructure alignment,…

Read article

Manufacturing & CPG Enhance Customer Experience Supply Chain

02/05/2026

by Liya Getachew

As seen on Packing Technology Today, originally published December 2025.

Historically, consumer packaged goods (CPG) manufacturers have grappled with inflexible supply chains, complex regulatory compliance, and the limitations of market research. While these challenges still persist today, the modern CPG manufacturer faces a new mandate: to adapt to rapidly evolving consumer demands for personalization, transparency and sustainability.

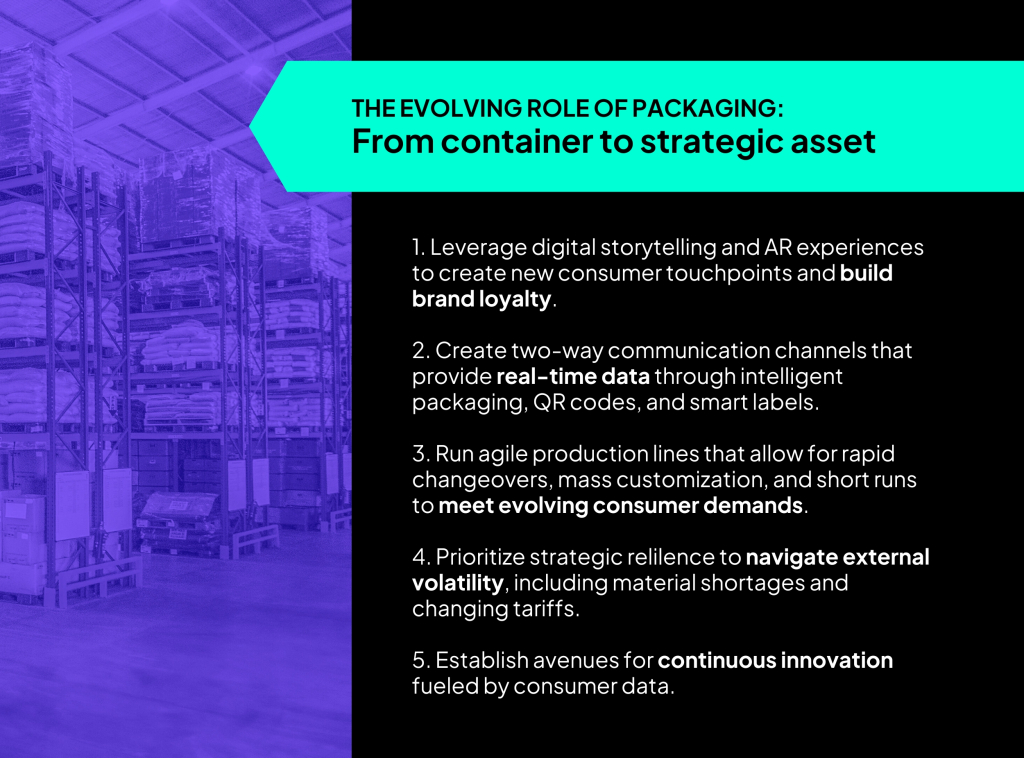

In this new era, packaging is being pushed to do more than ever before. It’s evolving from what was once a simple, passive container to a strategic tool for brand engagement and operational agility. The shift rise requires a fresh perspective on the “consumer-driven factory”, where packaging serves as a direct link between the consumer and the supply chain. It acts as a feedback loop, brand communication platform, and an agile component of production — making it a powerful strategic asset.

Innovative packaging presents a unique and significant opportunity for manufacturers. It creates a direct customer experience touchpoint, which involves using packaging as a collaborative platform for various business functions, such as marketing, branding, and product development. For example, to engage with consumers directly, companies can implement digital storytelling through QR codes that link to customer surveys or product information, as well as smart labels that track usage or trigger re-ordering.

By leveraging new advancements in technology, such as Augmented Reality (AR), companies can create experiences that offer a personalized digital brand interaction with consumers. These include virtual try-ons for categories like apparel and cosmetics, product placement for better visualization of products in their own spaces before purchase, and interactive product demonstrations, to name a few. By transforming packaging into a two-way communication channel, companies not only enhance customer experience but also create a real-time data source that informs production decisions.

Manufacturers are growing increasingly conscious of the unpredictable global trade environment and changing tariffs that are putting new pressures on packaging teams, affecting material costs and supply chain stability. Due to the frequent policy changes regarding tariffs, packaging manufacturers must manage this uncertainty through the adoption of flexible practices. This external pressure should be a key consideration with the consumer-driven factory model, as the ability to adapt quickly is no longer a luxury but a necessity. Packaging, an agile component of production, is required to respond quickly to these external shocks.

This agility is built on a foundation of technology that moves beyond traditional long runs and rigid production cycles. Examples of this include the utilization of digital printing for mass customization, short runs, and on-the-fly design changes, as well as the implementation of advanced automation and robotics for rapid line changeovers, minimizing downtime. These agile production methods allow CPG manufacturers to adapt quickly to material shortages, cost increases, and new designs, ensuring a seamless flow of goods to market.

Agile technology and principles are the ultimate solution for realizing value in packaging’s new strategic role. Data analytics, sourced directly from packaging touchpoints, such as when and where a product is scanned or consumed, can be used to inform real-time production schedules and inventory levels. This is much more accurate than relying on previous sales data and enables companies to respond to market shifts quickly and better manage demand. By integrating packaging design with a flexible production line, manufacturers can achieve new levels of efficiency and responsiveness.

Flexible lines also enhance innovation and sustainability by facilitating the use of sustainable materials and processes and enabling personalization and customization through the use of bespoke modules. Furthermore, these lines can provide simulation tools for testing new designs. This approach allows for a virtuous cycle of continuous improvement: consumer data drives design innovation, which is then enabled by agile production technology, creating new opportunities for market growth and competitive advantage.

The role of packaging has fundamentally changed, presenting both challenges and opportunities for CPG manufacturers. It is now a strategic, multi-purpose asset that directly links brands to their consumers and the market. Manufacturers must now embrace the dual role of packaging as both a digital data source and a flexible component of production. The key to mastering this transformation is through adopting agile technology and principles, which allow organizations to overcome challenges and turn volatility into opportunity. This proactive approach to packaging is a significant strategic differentiator, ensuring the CPG manufacturer remains relevant, responsive, and resilient in an ever-changing landscape. The container, once passive, has evolved into a direct and essential link to consumers and embracing this new role is the ultimate strategy for building a truly resilient CPG operation.

Business insights

Manufacturing & CPGDigital Engagement

To truly maximize deal value in manufacturing M&A, leaders must prioritize proactive digital infrastructure alignment,…

Read article

Manufacturing & CPGUKG

For manufacturers, having an efficient workforce management (WFM) system in place isn’t just a convenience—it’s…

Read article

Manufacturing & CPGSupply Chain

The global trade landscape is shifting rapidly, driven by recent U.S. tariff policies. Below are key considerations and…

Read article